4 Facts About Aluminum Composite Panels

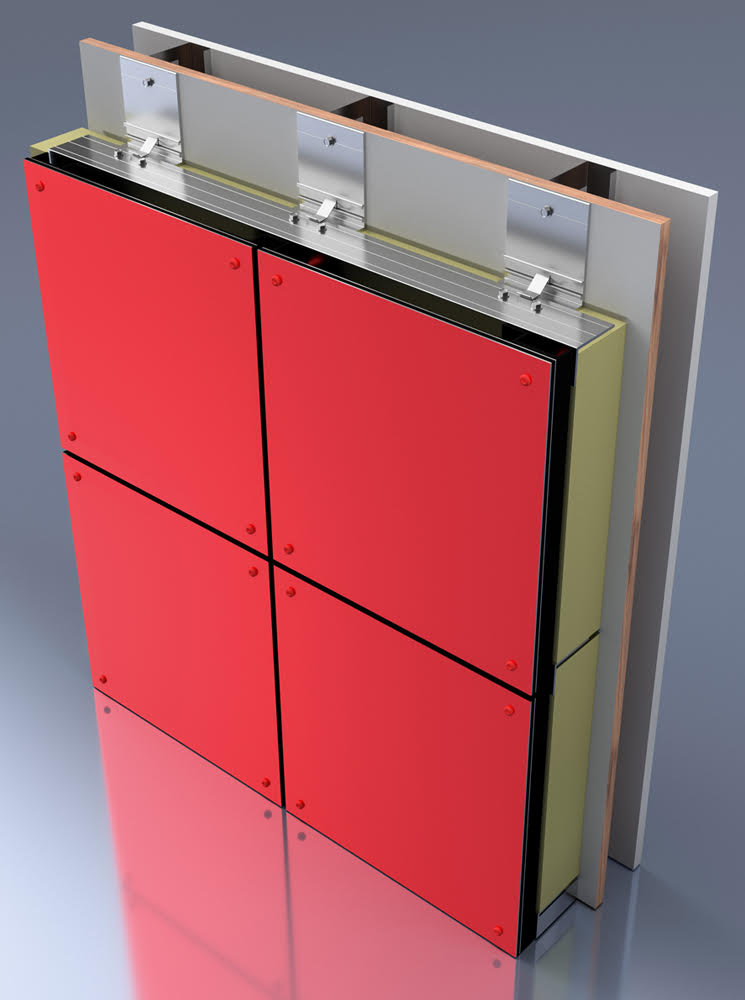

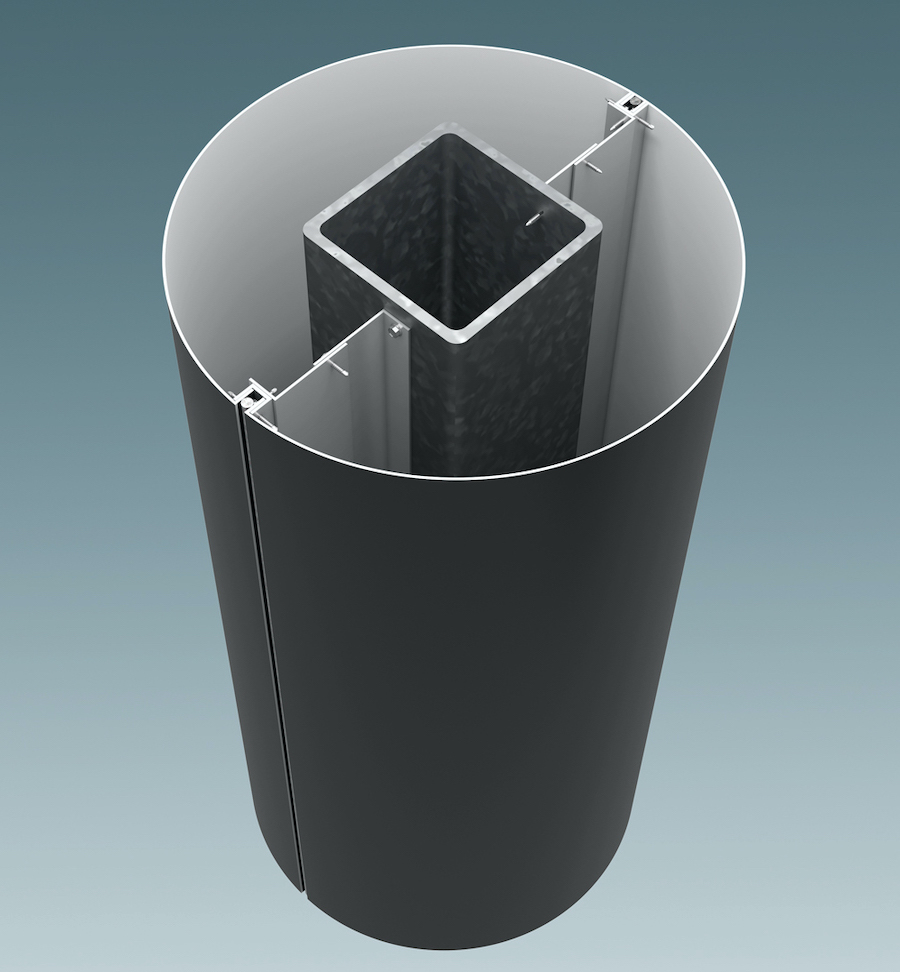

Aluminum Composite Panels, commonly known as ACP, represent a prevalent building material with diverse applications in both construction and signage. Comprising two thin, flat aluminum panels adhered to a non-aluminum center, this material often goes unnoticed in our daily lives. Despite its inconspicuous presence, aluminum composite panels offer intriguing facets that may not be widely known. Here are four noteworthy facts shedding light on the versatility and benefits of aluminum composite panels.

Extensive Color Options

Aluminum composite panels boast a palette of nearly 40 different colors, with the added flexibility of customization to suit specific building applications. Designers can emulate the appearance of aluminum, copper, zinc, or stainless steel, providing unparalleled design versatility characterized by clean and modern lines that endure the test of time. This diversity makes aluminum composite panels a unique choice, challenging to match in terms of aesthetic adaptability.

Remarkable Lightweight Characteristics

Following a complete installation, the finished weight of an aluminum composite panel averages a mere 2.5 pounds per square foot. This remarkable lightweight attribute coexists with exceptional durability and longevity, distinguishing it from alternative materials. The combination of structural resilience and reduced weight contributes to the practicality and ease of handling during the installation process.

Environmental Sustainability

Opting for construction with aluminum composite panels aligns with environmental responsibility, given that these panels are considered sustainable building materials. Typically crafted from approximately 85% recycled aluminum, these panels contribute to reducing environmental impact. Moreover, certain states may offer tax credits for such eco-friendly choices, while LEED credits from the U.S. Green Building Council may be attainable for buildings voluntarily incorporating aluminum composite panels. This underscores the commitment to sustainable construction practices.

Fire Resistance Compliance

Addressing global building codes, aluminum composite panels are available with cores composed of fire-resistant materials. Specifically engineered to meet stringent codes applicable to large structures such as skyscrapers and high-rise buildings, these panels ensure the use of non-combustible materials in adherence to building regulations. Prospective buyers should scrutinize the fire specifications of specific aluminum composite panels to ascertain compliance with their state's code requirements, emphasizing safety in building applications.

In the realm of construction, integrating Aluminum Composite Panels requires meticulous attention to detail. BIM Model Coordination, incorporating these panels seamlessly into Building Information Modeling (BIM), enhances the precision of design and construction processes. Ensuring the accurate representation of aluminum composite panels within a BIM model facilitates effective collaboration among stakeholders, promoting a streamlined and efficient construction workflow. Thus, the integration of Aluminum Composite Panels into BIM Model Coordination enhances project accuracy and efficiency, reflecting a forward-thinking approach to modern construction practices.

.png)